COAL AND ALUM PROJECT

Inform yourself about our projects around the area of "coal and alum".

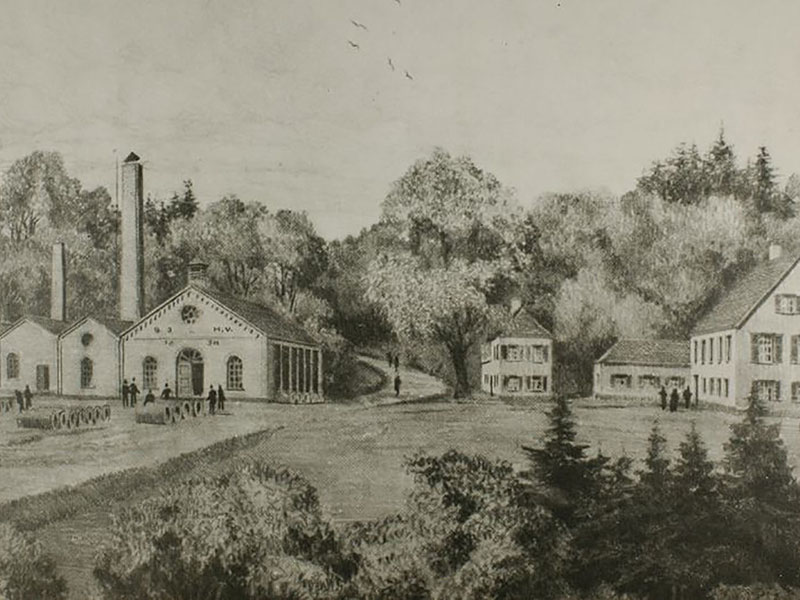

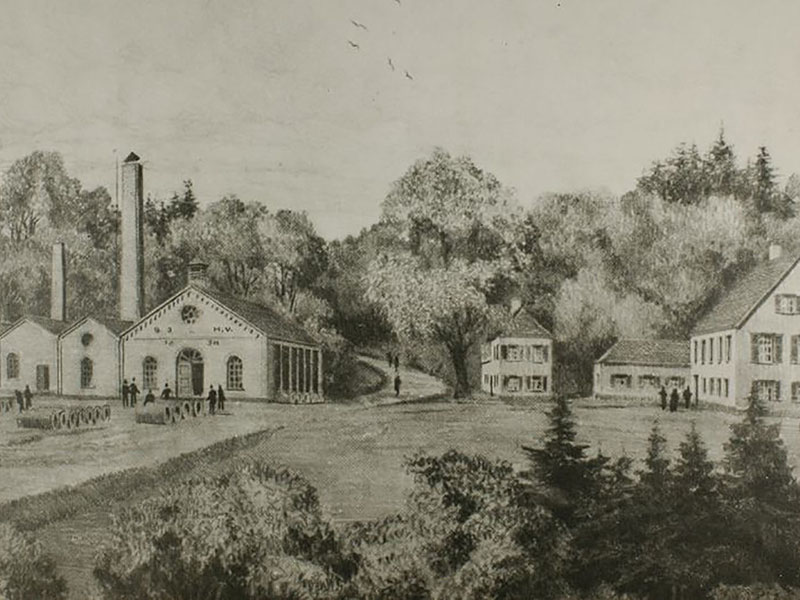

Illustration: General view alum hut

Illustration: Display board 1 at the Ennert car park

Coal and alum

The cultural landscape of the Ennert nature reserve is characterised in the Hardt area by the history of lignite mining and the alum production based on it. In the 19th century, the mineral salt alum was produced in three extensive factories (so-called alum smelters) on the ridge between Holzlar and Oberholtorf.

The raw material for this was lignite containing alum, which was extracted in a series of underground mines on the Holtorf plateau, as far as Vinxel and Hoholz. Brought in by trolley trains, the coal was piled up on heaps and "quietly" burned in them.

Alum was leached out of the ash in several stages, initially in the open air, using water in a chemical reaction. In crystallized form, it was a sought-after commodity that was used primarily in textile dyeing and in the production of leather, paper and glue, as well as in numerous processes in chemistry, pharmacy and medicine.

Around 1850, the alum factory on the Ennert-Hardt was the largest in the state of Prussia. Together with the mining industry, it was the most important employer in the region.

The mining history in the Ennert came to an end around 1875, when the chemical industry succeeded in producing alum more cheaply in a large-scale process. The mining and alum companies, which had meanwhile merged to form a joint stock company, then continued their activities on the banks of the Rhine in Ramersdorf, where they had already built a cement factory in 1855, the first on the territory of the present-day Federal Republic of Germany.

On the Ennert-Hardt, the soil formation of the present forest landscape (including dumps of production residues) and the remaining dense network of routes of the former infrastructure

(e.g. paths, railways, dams, water channels, ponds) and the structural remains of the alum smelters, the early industrial events can still be understood today.

The history trail "Lignite + Alum on the Ennert-Hardt", an information system set up by the Bonn-Rechtsrheinisch Monument and History Association in 2014 with the cooperation of the Holtorf-Ungarten and Holzlar citizens' associations and the Ramersdorf citizens' association, is intended to help. It consists of eight display boards, which are set up at eight points along a route from Holzlar to Oberholtorf. They refer to the respective localities and answer the relevant technical questions.

The display boards were designed under the auspices of the Monument and History Society together with the Holzlar and Holtorf-Ungarten Citizens' Associations; the costs were borne by the Bonn-Ennert Lions Club.

Further links:

The Ennert-Hardt-Hut

This is roughly what the Ennert-Hardt looked like in the middle of the 19th century, with no trace of trees or shrubbery (drawing by A. Henry, ca. 1853). The entire area between Holzlar and Holtorf was dominated by polluting factories that processed the lignite mined underground on the plateau between Hoholz, Vinxel and Holtorf into alum.

They were the largest employer in the nearby region and the largest alum producer in the state of Prussia. After 1875, production, which had begun in 1806, ceased. Nature overgrew the site and the memory of this early Rhenish industrial history faded. However, the Monument Society has refreshed this memory by searching for clues on site, researching archives, and organising lectures and excursions.

The filmmaker Georg Divossen from Bonn has documented the story of the research and visualization of this early testimony of the industry in Beuel in a video. A detailed film by him has also been published, available in bookshops and in the Bürgermeister-Stroof-Haus.

Further links:

Illustration: The Ennert-Hardt ironworks in the middle of the 19th century.